Darcy Partners recognized Circul8 as one of the Top 10 Innovators in the space for its high efficiency, low energy, zero chemical approach to ultra fine solids removal from spent fluids, highlighting its progress in commercializing at scale its technology in 2025, and reinforcing its leadership in base oil recovery and spent fluids reconditioning.

Reduced Drilling Efficiency.

Higher Well Costs.

Lost Revenue.

Operator. LMP. Solids Control Vendor. Waste Management Provider.

If you are managing spent OBM fluids using traditional methods, at least one of these applies to you.

Recover Value.

Restore Perfomance.

12 ppg OBM using 100% Recovered Oil | Recovered Oil | DF Measured |

|---|---|---|

Avg BHR | Avg AHR | |

Plastic Viscosity (PV): cP | 31 | 31.5 |

Yield Point (YP): lb/100 ft2 | 15.5 | 14 |

Gel Strengths 10-sec: lb/100 ft2 | 6.5 | 6 |

Gel Strengths 10-min: lb/100 ft2 | 9.5 | 8.5 |

HPHT Fluid Loss: ml/30 min | 1.2 |

_edited.jpg)

_edited_edited.jpg)

>60%

100%

>$5000

Recovery of diesel, LTMO or synthetic with no odour and no degradation.

Recycled into new diesel, LTMO or synthetic base fluids.

Recovered base oil value per 100 bbl of spent fluids and >$2000 in haul off and disposal costs from solids control enhancement.

Offshore

Optimize dryer performance and reduce ship to shore logistics.

Pad and extended reach drilling

Reduce solids loading, improve performance and minimize haul off.

Remote/ Environmentally Sensitive

Minimize disposal and supply logistics while enhancing ESG profile.

LMPs

Optimize inventory maximize storage and reduce new fluid cost.

Waste Management

Decrease disposal volumes and increase value per barrel.

Challenge

Extended use of high LGS fluids reduces efficiency, increased time to depth on complex wells and results in higher overall well costs.

-

Performance fluids composed of high stable emulsions make separation of colloidal solids very challenging.

-

Without chemical addition existing centrifuge capability has reached its limits.

-

Cuttings dryers offer high capacity at low cost but fluid recovery quality is marginal and requires dilution.

-

All options end with reduced performance and higher well costs.

Process

Chemical free surfactant destabilization yields improved fluid treatment performance and reduced waste

The Delta series of 100, 200 and 300 bpd systems use advanced thermochemical parameters to precisely manage the interfacial properties of fluids, manipulating their inherent characteristics at a molecular level to achieve optimized phase separation.

With no chemical addition, the destabilized fluid allows for efficient coalescence. Solids in the now destabilized fluid can be readily flocculated, dramatically enhancing the efficacy of standard centrifugation.

Recovered oil is chemically equivalent to the original base oil and ready to build up new fluid for even the most demanding application.

.png)

Put Drilling Fluids Back To Work

High Capacity. Small Footprint. Hot Shot Portable. Low Energy Electric. Single Operator.

-

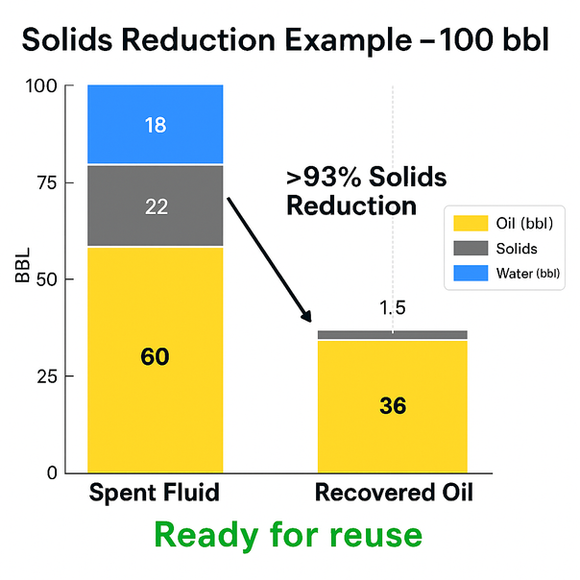

Dramatically enhance existing centrifuge performance with 60% base oil recovery.

-

Reduce disposal volumes by 40% compared with centrifuge alone.

-

Maintain fluid performance and reduce TDD by 2-3 days per well on pad and extended reach projects.

-

Minimize carbon footprint with 95% tCO2e reduction.

-

Maximize the value of every fluid barrel.

Our Partners

Ready to

Recover More, Waste Less, and Drill Better?

Fill out the form below and let Circul8's experts help

Press Release

The Challenge You Face. The Solution We Provide

.png)

Today’s high performance fluids drill deeper further and faster than ever before but are still composed of up to 80% diesel, LTMO or highly engineered synthetic base oil which operators and LMPs are forced to treat as consumable.

Separating these highly stable emulsions carrying excess colloidal solids from spent fluids is challenging the capability of existing centrifuge and dryer equipment and is often too costly or inefficient to be effectively managed by thermal, vacuum or electrophoresis.

Landfilling and injection provide cost effective and secure waste management solutions but represent assets whose lifespans are finite with additional space becoming increasingly challenging to permit and no oil recovery.

Circul8 revolutionizes the way spent fluid is managed by enhancing, not displacing, existing solids control systems producing equivalent base oil capable of meeting the demands of today's high performance fluids while optimizing revenue and value from increasingly regulated waste management systems.

With zero degradation and solids content as low as 2%, Circul8 recovered base oil has been independently verified to meet all KPIs for new mud builds while maintaining full stability after hot rolling. This allows for full recycling of the recovered oil, saving costs, improving drilling efficiency and reducing impact to the environment.

.png)